How often does the light-bulb moment happen and you suddenly realise what you need to do to and fix the fault in front of you?

Usually when you’ve given up and gone on to something else, right?

It was a lesson I learned early in life – where the answer, or path to finding the real issue, became clear during a night’s sleep. You ‘sleep on it’.

This week’s example is slightly different, and that’s perhaps the greater lesson: on when to listen to your gut/instinct.

For some reason, a driving force inside me said to dig out the non-working Solomon SL-20 solder station that stopped on me several years ago. For the purpose of the tale it’s a black box with wires and one day the lights stopped working.

For the technical minded it’s a great quality temperature-controlled soldering iron. So has some value at being repaired. A new one sells for $280.

That driving force said to figure this – it’s easy. The journey began by Google hunting any information I could. Ideally diagrams, especially a circuit diagram, or schematic.

The path was a bit cool (this is a piece of 1990’s technology), so there was not a lot of information around. The only circuit diagrams that resembled what I had in bits on the bench were in Russian. Yay. Lucky schematics are an international language.

Finding two versions of the diagram, I had at least a head-start.

Then the fun began, trying to relate the diagram to the actual. Probe for voltages and changes. Understand how the circuit worked.

Trusting the journey and knowing the more I understood the circuit the quicker/easier it would be to get to the end, know what was wrong and close the chapter.

A couple of hours go by…

The general circuit and voltages all check out, well within expected tolerance. Use of an oscilloscope (because I have one), confirmed the fundamentals were sound. It still wasn’t working.

Firstly; checking the fundamentals: the soldering iron itself. The heating element and temperature sensor were working. Static tests were 100%.

Those with experience know from time-to-time static tests and dynamic tests (under load) often vary. Take static tests at face value, to help eliminate obvious faults.

Checking in with a colleague to test his opinion on a few points. He shared and stated the obvious. That reinforced my faith I wasn’t missing anything. Of course, it still wasn’t working.

Jump forward to later in the day (it’s now late evening) and still driven by some internal force to fix this.

By this time I had enough evidence the circuit was working enough the output was to be the focal point. Clarifying; the output, that turns the heating element on/off was one of the first parts checked. It all tested fine. All voltages were okay.

Taking a step back with the fault-finding I focussed on continuity testing of cables as there were a number of connectors in the circuit – as points of mechanical connection, they can often be a weak link.

They all checked fine. But as I worked my way toward the circuit board something wasn’t adding up. Bypassing the circuit on the board should have lit things into life. It didn’t. This was very fishy.

Quickly and amidst confusion as I double and triple checked voltages I realised the bypassing wasn’t connecting the circuit where it needed to be connected.

There it was. The fault.

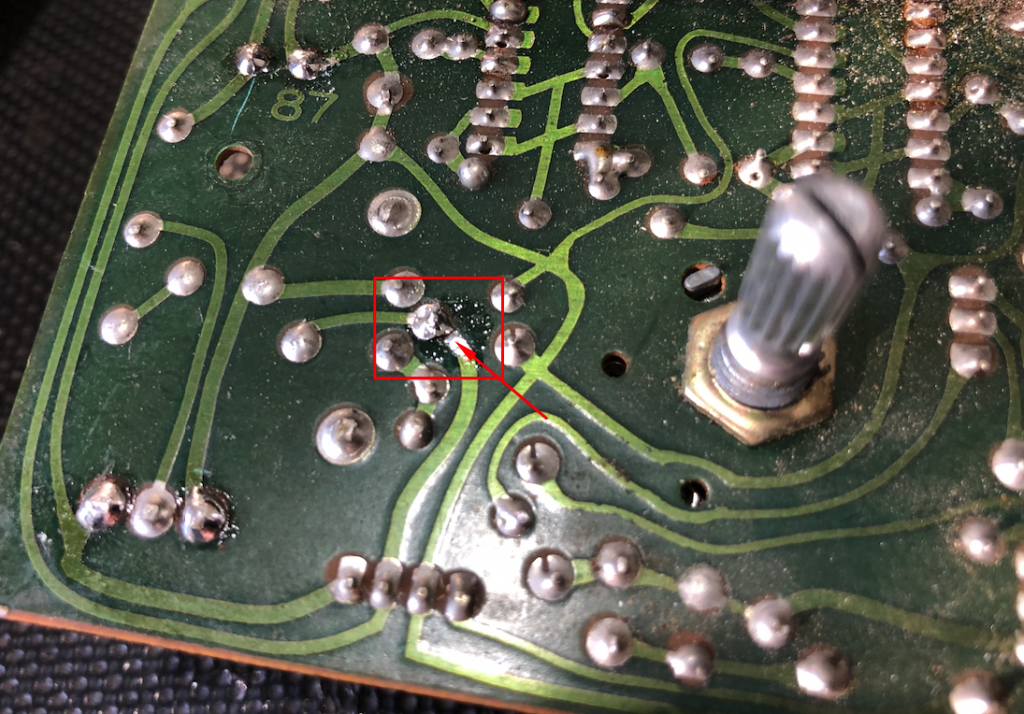

The break was on the circuit board.

As I started looking, I saw it. A neat break between the copper trace and the circuit pad the output Triac was connected to. A hairline break.

Quickly I cleaned and joined the break (the joys of having a new temperature-controlled solder station).

It sprang into life.

That it was working again was half the satisfaction. The second half was following the burning desire to resolve the fault. The blind faith it would be easy.

This would have been regarded as a throw-away item when it stopped working. Buy a new one. I don’t need to.

Cost of parts: $0.

Time: three hours.

Result: A reminder to follow that internal driver. You’ll surprise yourself what you can achieve, with a bit of time and your own resource.

Was this of value to you? If so and you feel the desire: Buy Me A Coffee